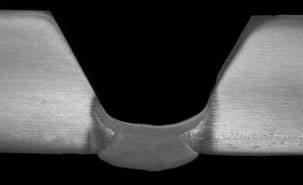

Discover a whole new principle of perfection with MULTIMATRIX

®

: with technical innovations and optimisations that are all perfectly coordinated in a complete system of power source, wire feeder and welding torch, guaranteeing smooth processes and flawless results. Now and in the future

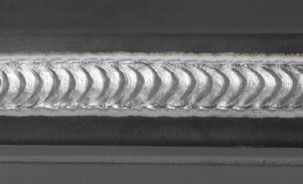

We strive not only to define configurations and create characteristics, but also to develop totally new and innovative welding processes. We focus firmly on the advantages for you: you benefit from continually optimised welding characteristics in all MIG/MAG processes – and therefore from less finishing work, more fields of application and higher quality results.

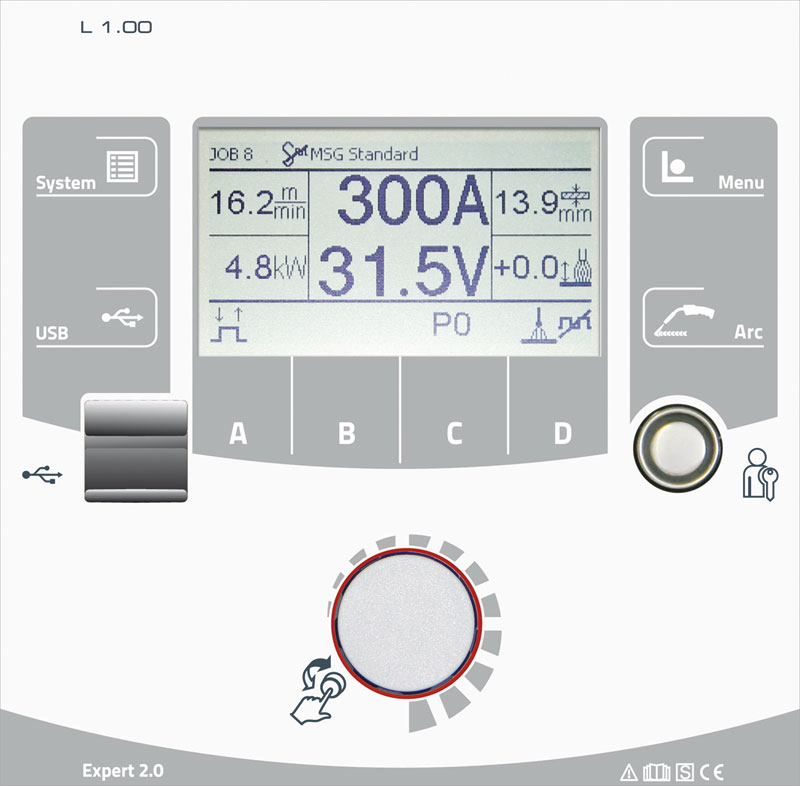

An essential part of our MULTIMATRIX

®

technology is the direct access to expert knowledge – combined and displayed in the Expert 2.0 control unit. It gives you all the important parameters at a glance for every welding task – and full control of your complete welding process.

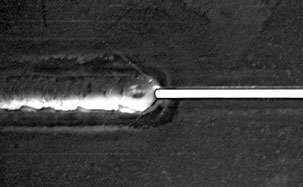

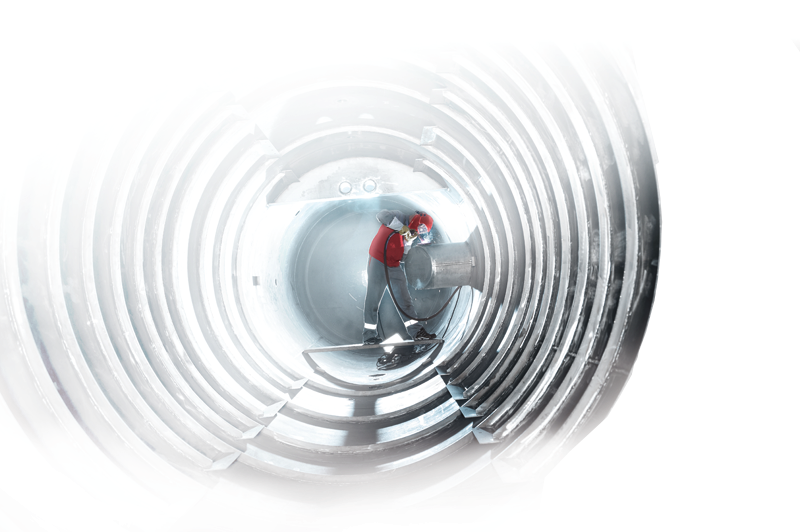

Precise wire feeding is the basis of every welding task. At the core of every work situation are short set-up times, a long service life and flexible usage options, which make the whole system exceptional. Therefore it was our duty to combine all of these features. We also added workplace comfort, low weight and manhole-appropriate dimensions.

-

reliable wire feeding

-

minimised set-up times

-

wide range of options – adjustable to individual requirements

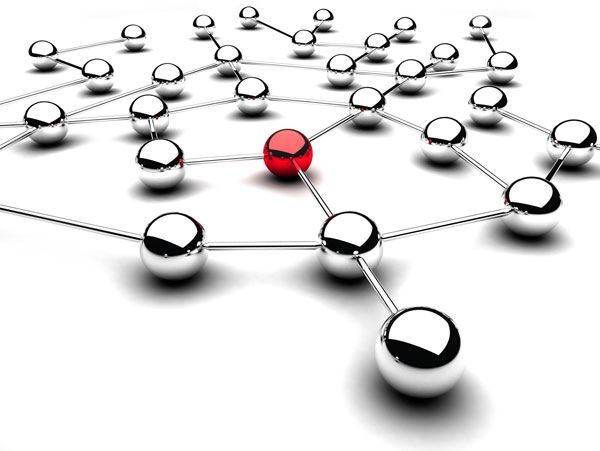

Manufacture efficiently, find potential savings and document every weld seam: the requirements for a quality management system vary considerably. The MULTIMATRIX® solution is very simple: ewm Xnet. With this network software, you are ideally positioned for the future – whether you are a regional specialist welding company or an internationally operating group.

-

online analysis, evaluation, reporting and documentation of logged welding parameters for each networked welding machine

-

convenient and easy-to-create graphical assignment of network subscribers based on a work facility floor plan

-

Online Monitoring: control and monitor the welding process for any number of welding machines from any number of PC workstations

Brochure Xnet

Brochure Xnet