EN 1090 WPQR Package

Available as a free download! *

* On purchasing a relevant welding machine

Continue to the certification process

Continue to the certification process

Planning

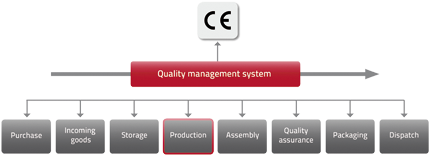

PlanningFirst, you should keep in mind what the certification means for your operation in detail: namely, the mapping of the entire operation process from purchasing to goods receipt, warehousing, production and assembly, up to packaging and shipping – for each component!

Publications and manuals with form templates and checklists for EN 1090 are issued by certifying bodies.

/// The introduction of a quality management system in a welding company involves the entire operational sequence. The aim is to become certified and obtain the CE marking.

Qualification of employees

Qualification of employeesYour team should be as ready for the EN 1090 as you are. And verifiably so: You require personnel with certain qualifications for the production process. For the welding process, such staff are certified welders and a suitable welding supervision team (EXC 2 – SFM/EWS welding expert). In the publications of the certifying bodies, you find further information about the qualification requirements of all areas.

Introduction of a factory production control system (FPC)

Introduction of a factory production control system (FPC)A FPC allows for traceable quality proofs where required. Here, written manufacturing notes are initially created for each work step. Compliance is checked in production. A manufacturing note must be described in such a way that the required results and qualities can be reliably achieved.

Processes where quality is not easily verifiable after production are known as special processes. EN 1090 states that manufacturers need to ensure that the required level of quality is also maintained at all times when carrying out these special processes. An existing system in accordance with EN ISO 9001 is sufficient for the requirements.

Qualification of the welding processes

Qualification of the welding processes

/// The individual stages involved in the certification process

Welding process qualification is achieved in the following steps

A. Preparing a pWPS (preliminary Welding Procedure Specification):

For each weld seam, a WPS is required – meaning a written welding procedure specification. These instructions for the welder contain e.g. information for compiling parts, about preheating, about the welding procedure, about rework etc. For this, a preliminary WPS is created initially, a so-called pWPS.

B. Weld sample creation:

Based on the information provided in the preliminary pWPS, a weld sample is created in the presence of a tester.

C. Welding procedure test WPQR (Welding Procedure Qualification Record):

The weld sample created based on the pWPS is tested both non-destructively and by means of destructive testing methods. If this welding procedure test is successful, a WPQR certificate is issued as evidence of the suitability of the pWPS. The pWPS then becomes a qualified WPS. Based on a WPQR certificate, further WPS can be created. A WPQR certificate is issued to the person who has had the welding procedure test carried out. Consequently, every welding company would need to have its own WPQR certificates drawn up for the various seam types using different welding procedure tests in order to ensure qualified welding procedure specifications are available for reference. This procedure, however, is very time-consuming and costly. But it is also quite simple: Because, according to EN 1090, WPQR certificates for standard welding procedures and the associated welding procedure specifications can be transferred to other users.

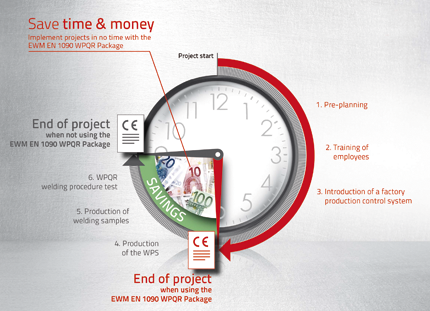

This saves time and money!

Certification

CertificationYou enter into a contract with a certifying body for the inspection and certification of your FPC system according to the Building Products Guideline. In addition to demonstrating a functioning quality management system throughout the entire operation, you are also required to demonstrate the qualification of the welding processes used in your company. This proof must already exist for certification. This is where ewm comes into play because we can simplify this time-consuming and costly qualification process: We have already pre-certified the respective welding procedure specifications for you and bundled them in one package.

/ / / You purchase the welding procedure specifications only once for all device series and use them time and again!

Continue to a simple solution

Continue to a simple solution

Save time and money during the qualification of welding processes: With the ewm EN 1090 WPQR Package you have everything you need: WPQR certificates and welding procedure specifications for almost 90% of common welding applications; applicable for many ewm welding machines and easily expandable.

Usable for the following ewm welding machines and welding consumables

Usable for the following ewm welding machines and welding consumables

There is simply more in it for you:

The ewm EN 1090 WPQR Package is universally usable for ewm welding machines of series alpha Q, Phoenix, Taurus Synergic or Picomig. This qualification may also be used retroactively for all previously purchased inverter machines mentioned above (manufactured in 2010 or later)!

/// The cost of a welding procedure test for a single pWPS – and thus ultimately for a single WPQR certificate – is between 1,100 and 3,000 Euro. With an average of seven WPQR certificates required by one company, the sum of 10,000 Euro is quickly reached and even exceeded.

You have welding machines from other manufacturers and would like to have welding procedure specifications according to EN 1090 for these devices? Here too, ewm has a solution: The use of qualified ewm welding consumables. Regardless of the welding machine, these tested ewm welding consumables can be used. A list of welding consumables can be found here.

Request your DEMO version free of cost

Request your DEMO version free of costAvailable as a

free download! *

* On purchasing

a relevant

welding machine

We will get back to you soonest.

EWM AG

Dr. Günter-Henle-Straße 8

56271 Mündersbach

Germany

Tel.: +49 - 2680/181-0

Fax: +49 - 2680/181-244

E-mail: info@ewm-group.com