Film ab

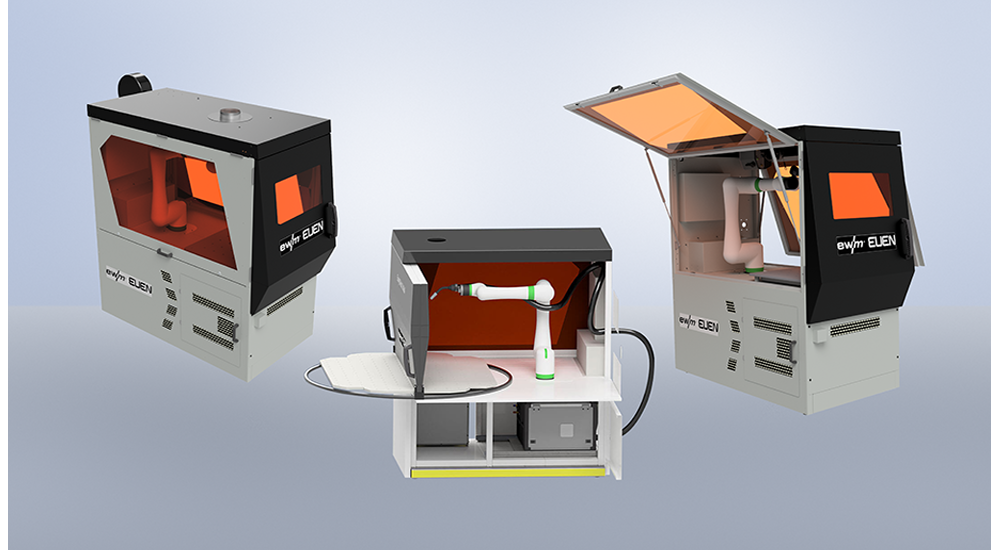

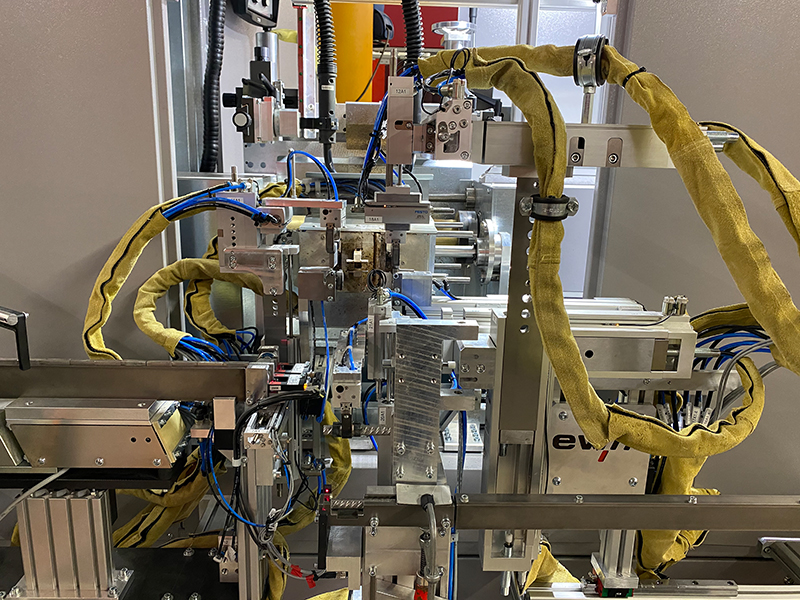

Systemkomponenten für das automatisierte Schweißen

Höchste Qualität in drei Buchstaben − EWM

Beste Ergebnisse im kompletten EWM-System: EWM-Produkte sind für höchste Qualität bekannt.

Unsere Stromquellen haben eine extrem hohe Einschalt- und damit Lebensdauer, von uns garantiert.

Drahtvorschubgeräte, Zwischenschlauchpakete und Schweißbrenner sind hochwertig

und optimal aufeinander abgestimmt.

Schreib uns eine Nachricht!

Kontaktanfrage

EWM − Dein Partner für

Schweißtechnik aus einer Hand

Rundum-Service heißt für uns: individuelle entwickelte Lösungen, Schulungen

und Unterstützung sowie Inbetriebnahme und Wartung der Anlagen.

Immer in deiner Nähe — und schnell für dich da!