BlueEvolution®

The Sustainability Initiative from the Inventors of the “Welding Code”

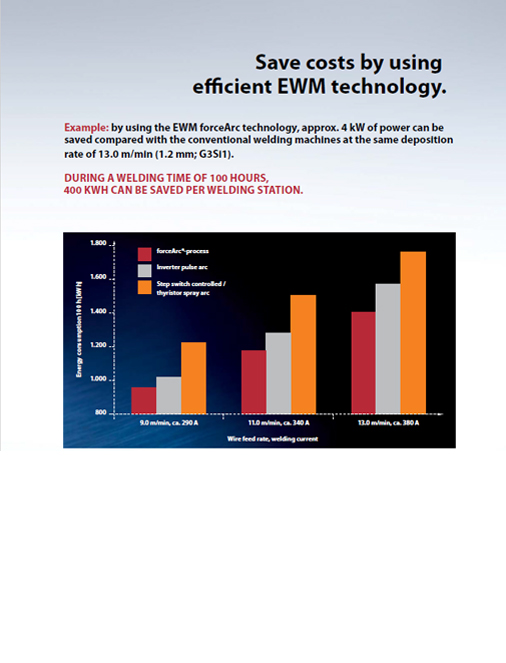

As a leading technology company, we support your contribution towards reducing CO2 emissions with our BlueEvolution® sustainability initiative. After all, a weld can only be perfect if the welding process conserves energy and raw materials. With our resource-saving inverter technology and energy-reducing joining processes, we unite economic efficiency and eco-friendly techniques.

Read more about the

Sustainability Initiative BlueEvolution® More about

Sustainability Watch Video

BlueEvolution

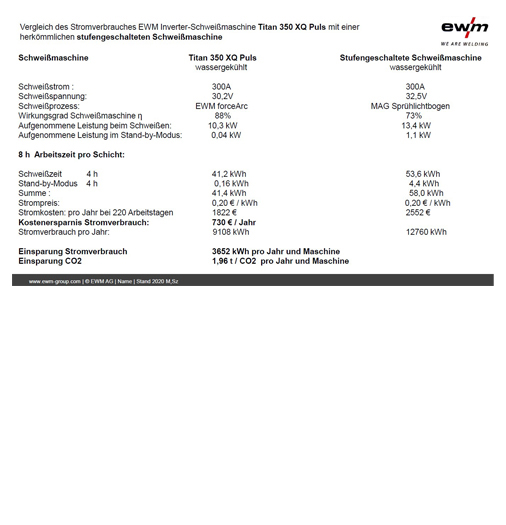

What causes energy loss during welding?

- Longer hose packages and longer grounding cables lead to higher power consumption.

- Hose packages and grounding cables with smaller cross-sections increase the power consumption.

- When the welding current is the same, water-cooled welding torches lose more energy than gas-cooled ones due to the smaller Cu cross-sections.

- Although an effective larger water pump uses more energy than a small water pump, better torch cooling reduces the need for consumables.

- Stronger fans in the power source have a greater power consumption than lower-performance fans, but better cooling translates to a longer duty cycle of 60%/100%. At the same time, the longer duty cycle represents an additional reserve in the power source, lowers the temperature in the power source and thus significantly increases the service life of the welding machine.