Arc deflection when welding pipes and metal plates? –

Magnetism could be the cause

Why should you degauss?

Arc deflection caused by magnetism is a thing of the past.

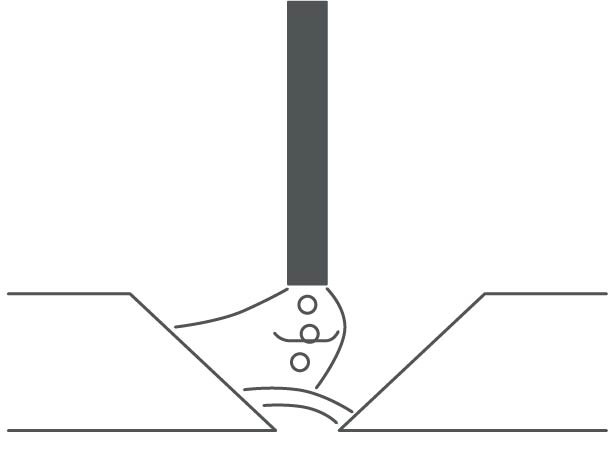

(Residual) magnetism in steel components causes instability and deflection in the arc and can lead to pores and lack of fusion. The effect may be so great that welding is impossible. Magnetism is therefore undesirable when welding steel.

-

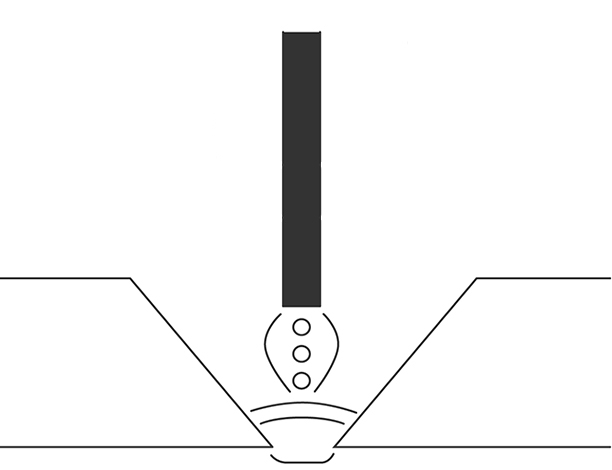

Without degaussing

» Inadequate welding results mean considerable finishing work, loss of time and high additional costs

-

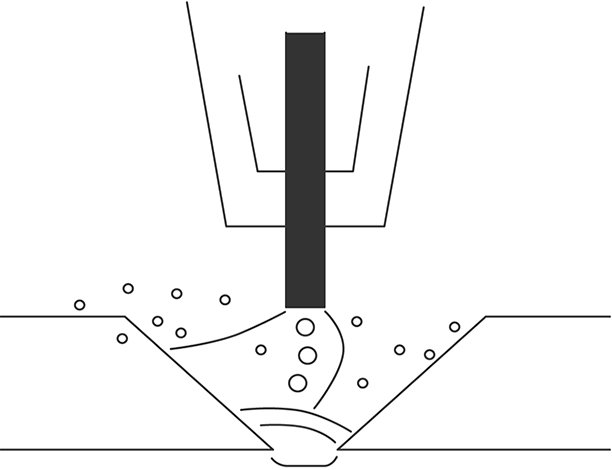

With degaussing

» Reduce costs, conserve resources and increase quality through high-quality welding results, less finishing work and reduced material and gas consumption

-

Workpiece is degaussed

» no arc deflection

Workpiece was degaussed with the Degauss 600 or Pico 350 cel puls pws dgs

MMA welding

MIG/MAG welding -

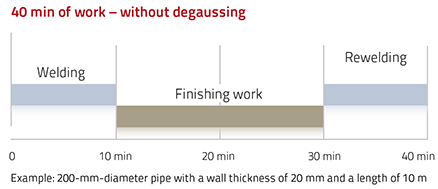

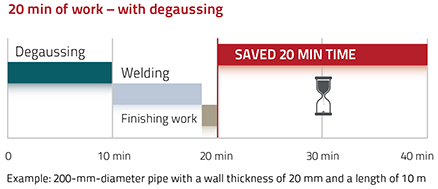

20 min of time saving – with degaussing

-

Outstanding welding results

- Stable arc

- Even droplet detachment

- Spatter-free

- Good sidewall fusion

-

Degaussing is easier as finishing work

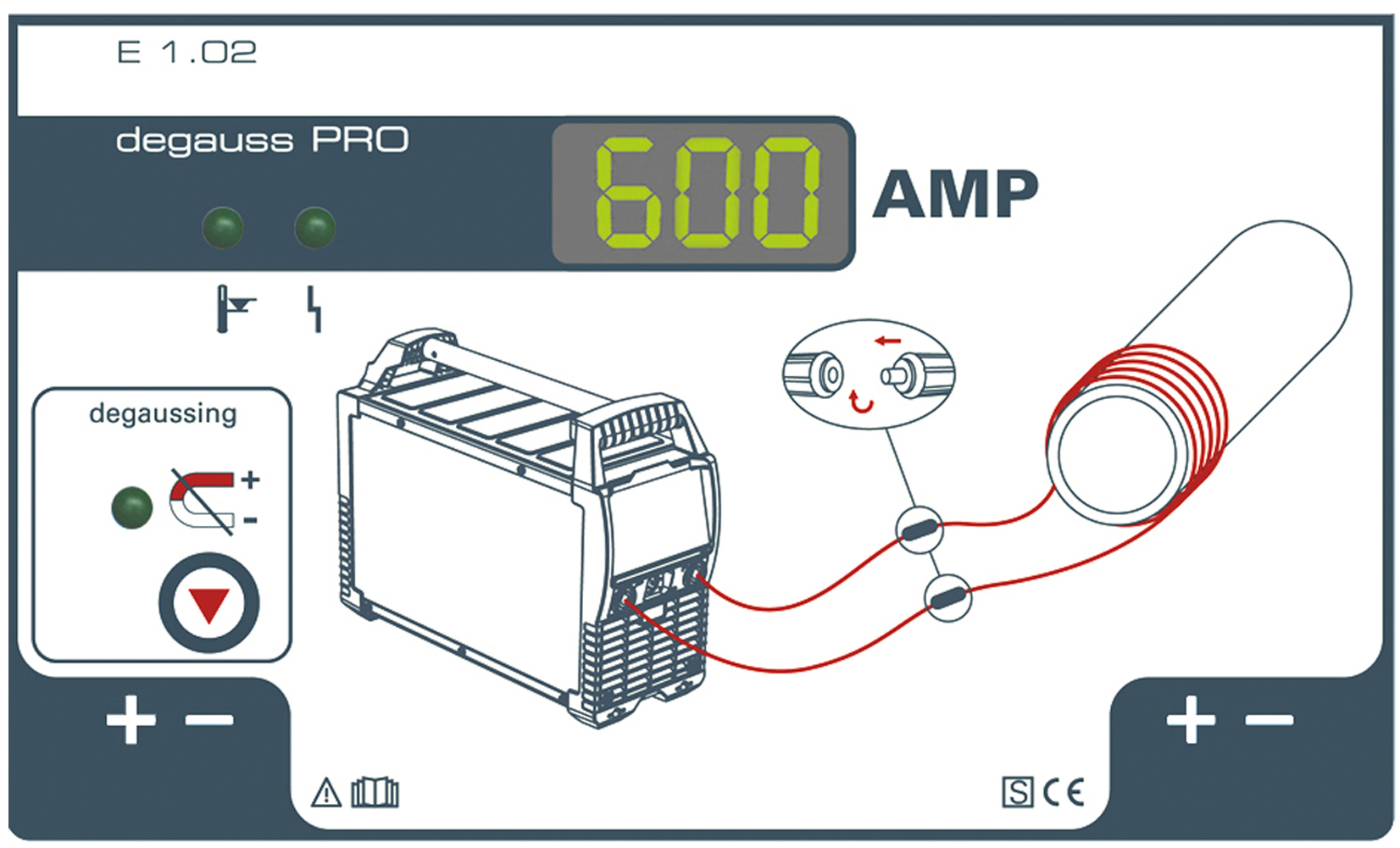

Magnetism caused by the mechanic separation of components, filing in preparation for welding or due to grinding processes occurs particularly frequently. For high-quality welding results, we recommend degaussing after mechanical processing and before the actual welding process. Application is very easy thanks to automatic running of the degaussing program (Application 1).

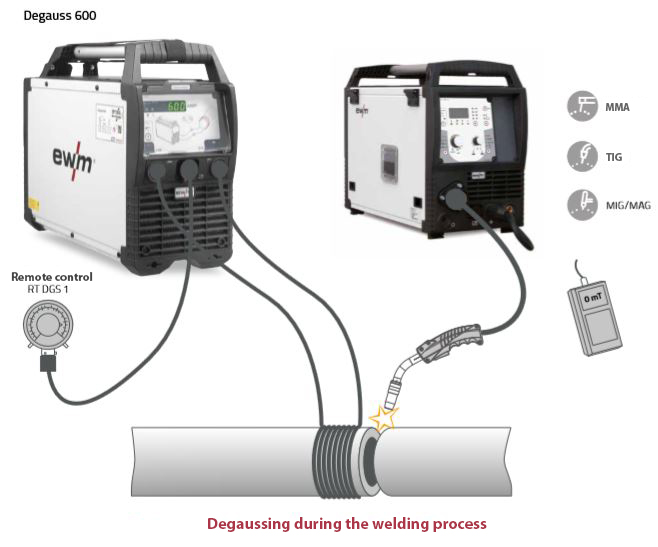

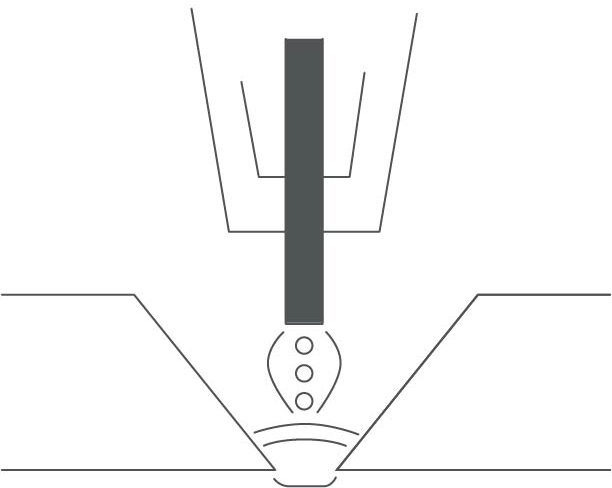

With very long, thick-walled and hard-to-reach components which are heavily magnetised, the magnetic field may return after degaussing. This will lead to arc deflection during welding. In this case, we recommend the “activgauss” function. Here, an opposing active magnetic field is generated during the welding process (Application 2). *

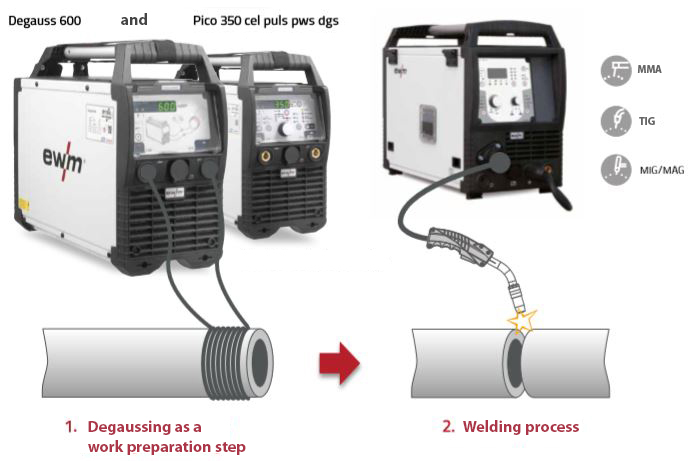

Application options for Degauss 600 and Pico 350 cel puls pws dgs

-

Application 1: degaussing

-

Application 2: activgauss

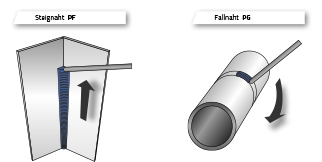

Degaussing of pipes and metal plates

Degauss 600

The Degauss 600 is suitable both for degaussing before the welding process and degaussing during the welding process.

Degaussing and welding with a single machine

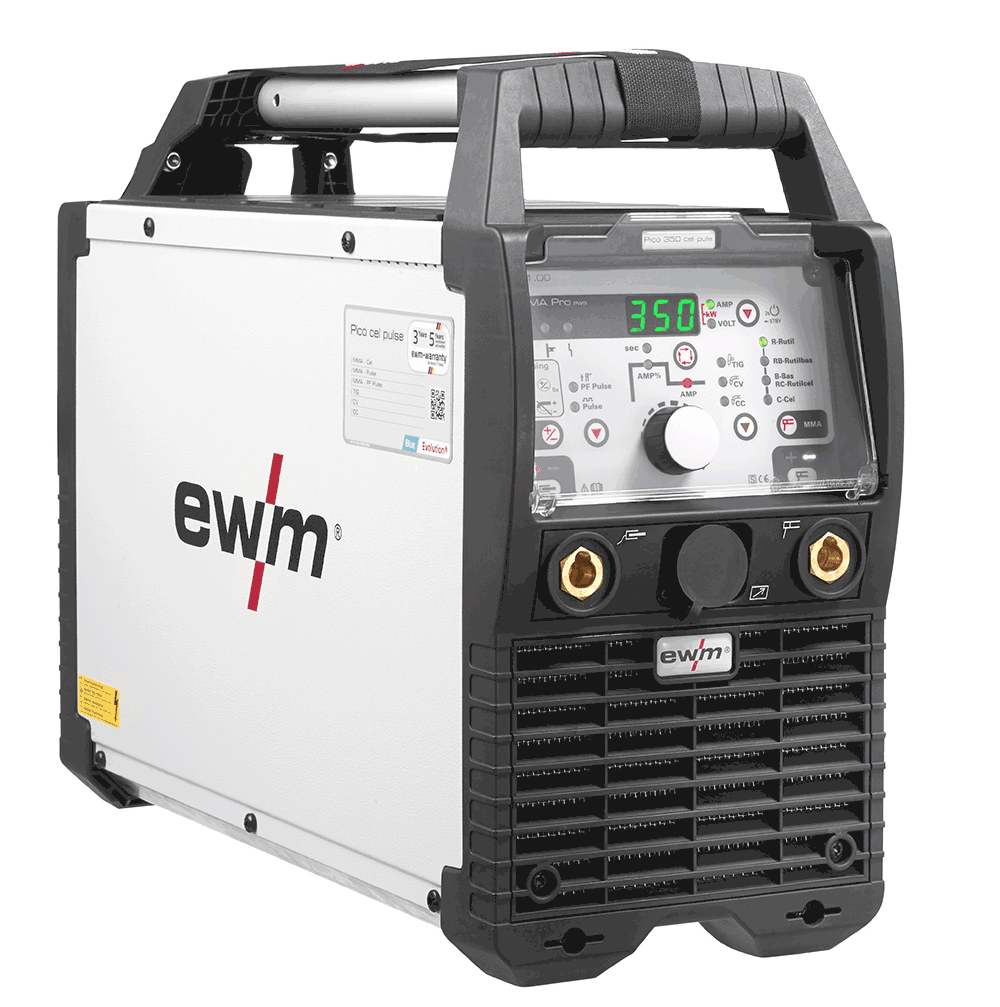

Pico 350 cel puls pws dgs

Resistant against cold, heat, rain and dirt, incredibly robust for the toughest of applications and ideal for various operating sites thanks to its light weight:

- 100% safe for vertical-down welding of cellulose electrodes

- MAG welding with Pico drive 4L or Pico drive 200C wire feeder

- Degaussing of pipes and metal plates before welding

Satisfied with the EWM solution:

Terranets bw GmbH